UAV Solar Inspection SOP: From Pre-Flight to Processing

A comprehensive guide to standardized operating procedures for solar farm inspections using drones, ensuring actionable data collection.

Read More →There's a lot of talk about drone docks as the modern, automated solution for renewables monitoring. But do they make sense for you? By the end of this post, you'll have a formula and clear case breakdown to bring to decision-makers in your O&M group.

There's a lot of talk about drone docks as the modern, automated solution for renewables monitoring. DJI is building them, Skydio is pushing them, and the most tech-forward companies in your industry are adopting them. Docks seem like the hottest upgrade to the aerial intelligence stack.

But do they make sense for you?

That depends. By the end of this post, you'll have a formula and clear case breakdown to bring to decision-makers in your O&M group.

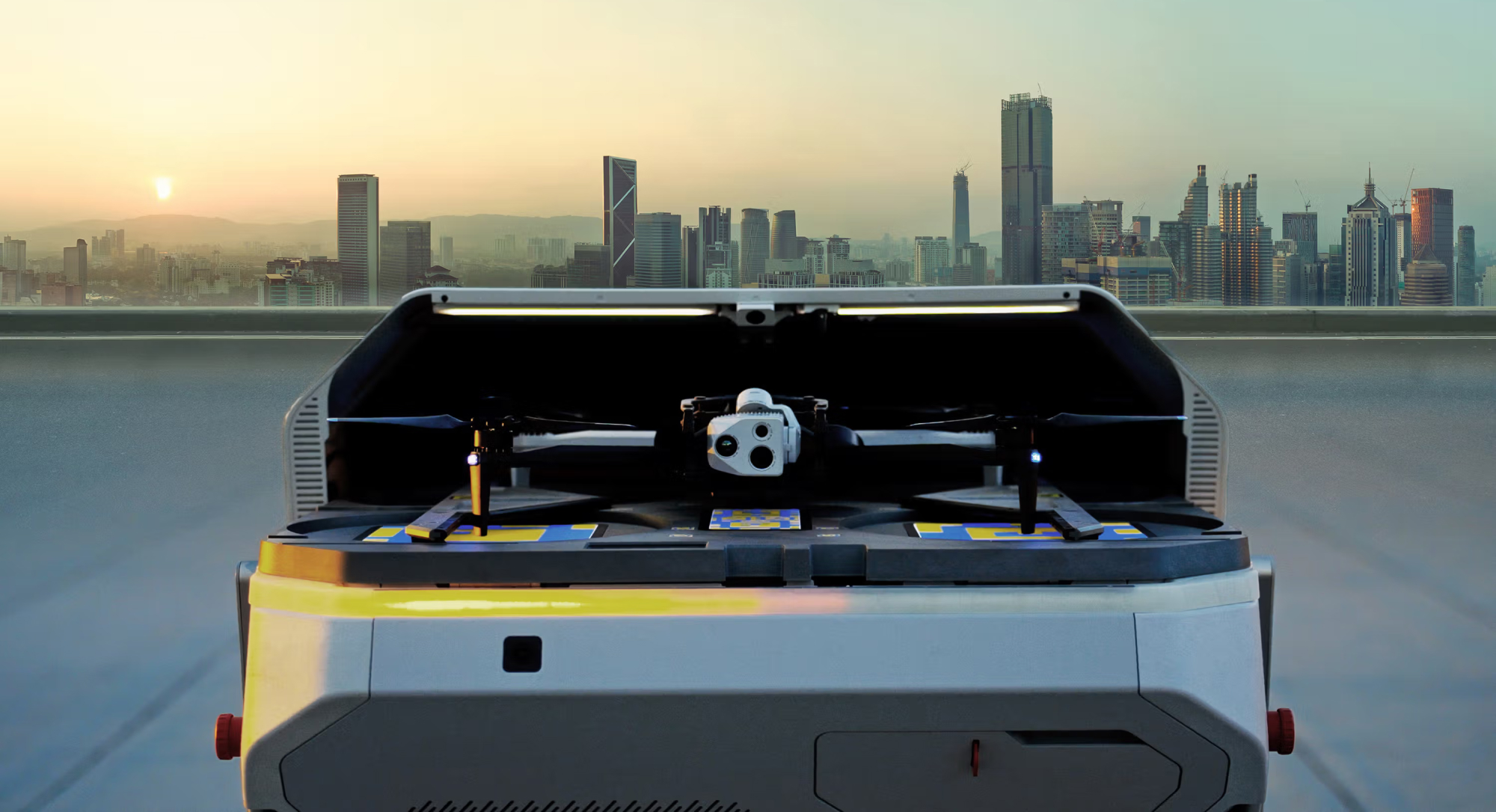

A drone dock is a weatherproof charging station that allows a drone to live permanently in the field near your assets. With the right regulatory approvals (e.g., BVLOS), the drone can be dispatched at regular intervals to collect RGB and thermal data with no human in the loop.

Most large solar farm operators task end-to-end aerial data providers like Raad with quarterly inspections. Once a quarter, Raad dispatches a certified thermal pilot to collect infrared data, stitch it into a processed orthomosaic, and deliver a defect and O&M report. This enables operators to identify panel and string defects, address them promptly, and maximize the productivity and profitability of their assets.

Fill out a pilot profile on RAAD.com now and start receiving mission opportunities.

One of the biggest and least talked about challenges in solar farm operations is the delay between identifying a problem and actually getting it fixed.

When a fault occurs, it's not as simple as pressing a button. A pilot has to be physically dispatched to the site, often driving hours to reach remote locations. In some cases, it can take days before they even arrive. Then, once the drone collects the imagery, the data still needs to be uploaded and processed, sometimes adding another 12 hours or more. During this entire window, the site is losing thousands of dollars in potential energy output. Nevermind the liability associated with having another contractor driving through the solar farm…

Now, imagine replacing that delay with an instant response.

With a drone dock permanently stationed on-site, deployment happens within seconds of an issue. The drone launches automatically, captures the necessary data and, with Raad's system, that data begins processing while the drone is still in the air.

What once took three days now happens in real-time. Your team receives actionable insights the same day, enabling you to swap and repair panels faster than ever before, keeping your site producing at peak efficiency.

Imagine you've been operating a 100 MW solar farm for two years. You're evaluating whether to continue booking quarterly drone pilot inspections or to install a turnkey dock solution.

Baseline assumptions:

Value per MW/year:

$320 (O&M savings) + $766.50 (1% energy gain) = $1,086.50/MW/year

Break-even size:

$24,000 ÷ $1,086.50 ≈ 22.1 MW

If your farm is 22 MW or larger, a dock makes sense purely on cost + efficiency gains.

The pure economics are only part of the story:

The smartest solar operators know the real value of docks isn't just beating the cost of quarterly manual flights. It's the ability to scan as often as needed without paying more.

Analyze the financial viability of automated drone docks vs traditional pilot-based inspections

✅ Drone docks are financially viable for your 100 MW solar farm. You'll save approximately $84,650 annually while gaining operational benefits.

Our sales team can help you design a custom drone dock solution for your solar operations. Get a detailed proposal and ROI analysis tailored to your specific requirements.

Contact SalesFill out a pilot profile on RAAD.com now and start receiving mission opportunities.

Chief Executive Officer

Repeat entrepreneur on a mission to modernize how we understand the infrastructure we all rely on.

A comprehensive guide to standardized operating procedures for solar farm inspections using drones, ensuring actionable data collection.

Read More →